Implementing lean construction principles in engineering firms can significantly enhance project outcomes by minimizing waste and maximizing value. These principles, rooted in the manufacturing industry, focus on optimizing resources, improving quality, and fostering continuous improvement. Engineering firms that adopt lean construction methodologies can achieve greater efficiency, cost savings, and client satisfaction, making it a valuable approach for firms aiming for accuracy and reliability in their projects.

Understanding Lean Construction Principles

Lean construction is a relationship-oriented, production management-based approach to project delivery that emphasizes the management and design of construction processes. Unlike traditional methods that focus primarily on the final product, lean construction aims to maximize stakeholder value and minimize waste through collaboration among construction teams (source).

The principles of lean construction are founded on six key tenets, as defined by the Lean Construction Institute (source): * Respect for People: Recognizes the essential value of all team members in the construction process. * Optimize the Whole: Encourages thinking about the entire project and its needs rather than just individual components. * Eliminate Waste: Focuses on identifying and eliminating waste in all forms. * Focus on Flow: Aims to maintain a continuous, uninterrupted workflow. * Generate Value: Seeks to understand value from the customer’s perspective and deliver it effectively. * Continuous Improvement: Encourages constant learning and improvement in practices.

Historically, lean construction principles borrow heavily from the manufacturing approach developed by Toyota after World War II. Within the construction industry, these principles and practices were developed independently by early contributors like Greg Howell and Glenn Ballard, who advocated for a shared-leadership system over a traditional top-down approach. The Lean Construction Institute (LCI) was formed in 1997 by Ballard and Howell to further develop and disseminate knowledge about lean construction (source, source).

The core objectives of lean construction are to eliminate waste and maximize value. Waste is categorized into eight major types: defects, overproduction, waiting, not utilizing talent, transport, inventory, motion, and over-processing (source). In contrast, maximizing value involves a thorough understanding of what the customer values, considering the entire lifecycle of the project, and optimizing construction processes to deliver a superior final product (source).

For engineering firms, implementing lean construction principles can lead to significant benefits such as reduced waste, cost savings, safer job sites, and faster project completion. Additionally, it fosters an environment of innovation and collaboration, ultimately leading to improved project outcomes (source, source).

Application of Lean Construction in Engineering Projects

Lean construction, as a project management approach, seeks to reduce waste and increase value in engineering projects. It is a project delivery process that uses Lean methods of maximizing stakeholder value while reducing waste by emphasizing collaboration between teams on a project (source).

Identifying Common Sources of Waste in Engineering Projects

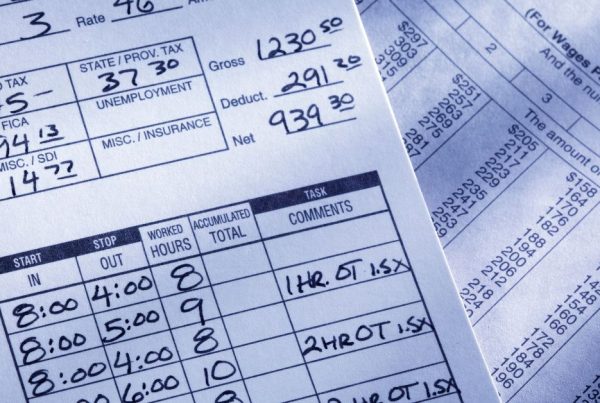

Lean construction identifies eight different types of waste that can occur during projects: Over/Under Production, Waiting, Unnecessary Transportation, Over/Under Processing, Excess Inventory, Unnecessary Motion, Defects, and Unused Creativity of Team Members (source). These wastes can significantly impact the efficiency and cost-effectiveness of engineering projects.

Strategies for Implementing Lean Construction Principles

-

Just-In-Time Delivery: This strategy involves the timely delivery of materials and services so that they are available just when they are needed. This helps to minimize the waste associated with overstocking and underutilization.

-

Continuous Improvement (Kaizen): This involves the continuous evaluation and improvement of processes and methods used in engineering projects. It encourages the elimination of waste, the maximization of value, and the improvement of productivity and efficiency.

-

Integrated Project Delivery (IPD): This is a collaborative approach that involves all stakeholders in a project. IPD aligns the owner, design team, and construction team onto a single contract, fostering collaboration and efficiency, and reducing waste (source).

Case Studies: Successful Implementation in Engineering Firms

Several case studies highlight the successful implementation of Lean Construction principles in engineering firms. For instance, the application of Lean Construction in the construction of Pixel office buildings in Poznań, Poland, led to significant improvements in the efficiency and cost-effectiveness of the project (source).

Other case studies featured on Lean Construction Blog demonstrate the successful application of Lean principles in various contexts, from implementing the Last Planner System to the use of Takt Production models (source).

Minute7 and Lean Construction Principles

As a time tracking and expense reporting solution designed specifically for professional service firms, Minute7 can play a crucial role in implementing Lean Construction Principles. By providing a platform for efficient time and expense tracking, Minute7 enables engineering firms to identify and eliminate waste, streamline their processes, and continuously improve their operations, all of which are key aspects of Lean Construction.

Benefits of Lean Construction for Engineering Firms

Implementing lean construction principles in engineering firms offers numerous benefits, enhancing overall project outcomes significantly.

Enhanced Project Efficiency and Productivity

Lean construction enhances project efficiency and productivity by eliminating waste and streamlining workflows. It emphasizes a smooth, continuous workflow with minimal interruptions and bottlenecks. This approach incorporates tools like value stream mapping, kanban, and 5S to improve project and operational quality while reducing costs. Lean construction’s pull systems ensure tasks only start when the preceding task is completed, reducing overproduction and excess labor (source, source).

Cost Reduction and Budget Adherence

By focusing on the elimination of waste and unnecessary steps, lean construction significantly reduces costs, helping projects adhere to budget constraints. This method scrutinizes each step in the value stream to identify areas of waste and inefficiency, allowing for continuous improvement. The result is a system that ensures the work of one process flows seamlessly to the next, reducing delays and cost overruns (source, source).

Improved Quality and Client Satisfaction

Lean construction aims to deliver high-quality projects that meet or exceed client expectations. Studies indicate that 84% of contractors using lean methodology reported higher quality construction, and 80% reported greater customer satisfaction (source). The focus is on delivering value to all project stakeholders and ensuring the results of one process are released to the next without delays, thereby improving overall project quality (source).

Better Team Collaboration and Communication

Lean construction fosters a culture of collaboration and teamwork, ensuring seamless cooperation among all parties involved in a project. It uses an Integrated Project Delivery (IPD) system to align the owner, design team, and construction team (and any additional contractors) onto a single contract. This alignment promotes better communication and collaboration, leading to improved project outcomes (source).

The above benefits make lean construction a valuable approach for engineering firms. Implementing lean construction principles can help these firms improve their project outcomes, reduce costs, enhance client satisfaction, and foster better team collaboration and communication. Minute7’s time tracking and expense reporting solutions can support the implementation of lean construction principles by providing a platform for efficient tracking of project hours and expenses. This, in turn, can enhance project efficiency, cost management, and overall project outcomes.

How Minute7 Supports Lean Construction Implementation

By integrating lean construction principles, engineering firms can achieve remarkable improvements in efficiency, cost management, and overall project outcomes. As these firms strive to minimize waste and maximize value, having the right tools in place is essential. Minute7 offers a robust time tracking and expense reporting solution that aligns seamlessly with lean construction methodologies.

Minute7’s platform provides engineering firms with the ability to accurately track time and expenses in real-time, ensuring no resources are wasted. The seamless integration with QuickBooks allows for streamlined financial management, reducing administrative burden and allowing teams to focus on core project activities. Additionally, the availability of web, iOS, and Android apps ensures that all team members, whether in the office or on-site, can consistently log their hours and expenses, contributing to a more accurate and comprehensive project overview.

Moreover, Minute7 supports continuous improvement (Kaizen) by offering detailed reporting and analytics. Engineering firms can identify patterns, inefficiencies, and areas for improvement through these insights, leading to more informed decision-making and process optimization. This aligns perfectly with the lean construction principle of continuous improvement, fostering a culture of innovation and excellence.

In conclusion, Minute7 not only simplifies time and expense tracking for engineering firms but also enhances their ability to implement lean construction principles effectively. By leveraging Minute7’s tools, engineering firms can ensure accurate tracking, reduce waste, and achieve better project outcomes, ultimately leading to higher efficiency, cost savings, and client satisfaction. Adopting Minute7 is a strategic step towards embracing lean construction and driving success in the competitive engineering landscape.